Abstract

Case Report

Cranioplasty with preoperatively customized Polymethyl-methacrylate by using 3-Dimensional Printed Polyethylene Terephthalate Glycol Mold

Mehmet Beşir Sürme*, Omer Batu Hergunsel, Bekir Akgun and Metin Kaplan

Published: 30 November, 2018 | Volume 2 - Issue 2 | Pages: 052-064

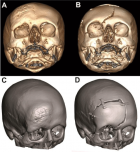

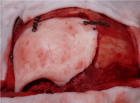

Cranioplasty is a reconstructive procedure for the repair of skull defects or deformities. Polymethyl-methacrylate (PMMA) is a commonly used alloplastic material when autologous bone is unavailable. However, manual shaping of bone cement for frontal and orbital bone defects is challenging and may not lead to cosmetically satisfactory results. Advances in computer-aided 3-dimensional (3D) design and printing technology allow the production of patient-customized implants with improved cosmetic and functional results. A 39-year-old female patient presented with right-sided frontal swelling and headache. Computerized tomography (CT) demonstrated a right frontal calvarial mass extending to the orbital wall. The boundaries of the lesion were marked using a 3D design software. A polyethylene terephthalate glycol (PETG) mold was manufactured with help of a 3D printer. Artificial bone flap was formed by pouring PMMA into the mold. After surgical resection of the calvarial mass, customized PMMA implant was applied with titanium mini plate and screws. The defect was closed properly with good aesthetic results. Production of customized PMMA cranioplasty implants with 3D printed molds is a useful technique and can be preferred for calvarial defects due to skull tumors, bone resorption and traumatic bone loss.

Read Full Article HTML DOI: 10.29328/journal.jnnd.1001016 Cite this Article Read Full Article PDF

Keywords:

Cranioplasty; Polymethyl-methacrylate; 3-Dimensional modelling

References

- Aarabi B, Hesdorffer DC, Ahn ES, Aresco C, Scalea TM, et al. Outcome following decompressive craniectomy for malignant swelling due to severe head injury. J Neurosurg. 2006; 104: 469–479. Ref.: https://goo.gl/U2LxpY

- Park EK, Lim JY, Yun IS, Kim JS, Woo SH, et al. Cranioplasty Enhanced by Three-Dimensional Printing: Custom-Made Three-Dimensional-Printed Titanium Implants for Skull Defects. J Craniofac Surg. 2016; 27: 943–949. Ref.: https://goo.gl/AcWSNu

- Kim JC, Hong IP. Split-rib cranioplasty using a patient-specific three-dimensional printing model. Arch Plast Surg 2016; 43: 379–381. Ref.: https://goo.gl/3TsAKv

- Kim BJ, Hong KS, Park KJ, Park DH, Chung YG, et al. Customized cranioplasty implants using three-dimensional printers and polymethyl-methacrylate casting. J Korean Neurosurg Soc. 2012; 52: 541–546. Ref.: https://goo.gl/4G8T8Z

- Aydin S, Kucukyuruk B, Abuzayed B, Aydin S. Sanus GZ. Cranioplasty: Review of materials and techniques. J Neurosci Rural Pract. 2011; 2: 162–167. Ref.: https://goo.gl/o3MGh7

- Golz T, Graham CR, Busch LC, Wulf J, Winder RJ. Temperature elevation during simulated polymethylmethacrylate (PMMA) cranioplasty in a cadaver model. J Clin Neurosci. 2010; 17: 617–622. Ref.: https://goo.gl/tBNxg3

- Iwama T, Yamada J, Imai S, Shinoda J, Funakoshi T, et al. The use of frozen autogenous bone flaps in delayed cranioplasty revisited. Neurosurgery. 2003; 52: 591-596. Ref.: https://goo.gl/B1LDYp

- De La Peña A, De La Peña-Brambila J, Pérez-De La Torre J, Ochoa M, Guillermo J. Gallardo, Low-cost customized cranioplasty using a 3D digital printing model: a case report. 3D Print Med. 2018; 4: 4. Ref.: https://goo.gl/eJwpRZ

- Pikis S, Goldstein J, Spektor S. Potential neurotoxic effects of polymethylmethacrylate during cranioplasty. J Clin Neurosci. 2015; 22: 139-143. Ref.: https://goo.gl/sia4LV

- Parthasarathy J. 3D modeling, custom implants and its future perspectives in craniofacial surgery. Ann Maxillofac Surg. 2014; 4: 9-18. Ref.: https://goo.gl/yECgLD

- Tan ET, Ling JM, Dinesh SK. The feasibility of producing patient-specific acrylic cranioplasty implants with a low-cost 3D printer. J Neurosurg. 2016; 124: 1531–1537. Ref.: https://goo.gl/RSLCgg

- Seitz, H, Marlovits S, Schwendenwein I, Müller E, Vécsei V. Biocompatibility of polyethylene terephthalate (Trevira® hochfest) augmentation device in repair of the anterior cruciate ligament. Biomaterials. 1998; 19: 189–196. Ref.: https://goo.gl/wSRJ9o

- Hatamleh MM, Cartmill M, Watson J. Management of Extensive Frontal Cranioplasty Defects. J Craniofac Surg 2013; 24: 2018–2022. Ref.: https://goo.gl/DGKFKz

Figures:

Figure 1

Figure 2

Figure 3

Figure 4

Similar Articles

-

Cranioplasty with preoperatively customized Polymethyl-methacrylate by using 3-Dimensional Printed Polyethylene Terephthalate Glycol MoldMehmet Beşir Sürme*,Omer Batu Hergunsel,Bekir Akgun,Metin Kaplan. Cranioplasty with preoperatively customized Polymethyl-methacrylate by using 3-Dimensional Printed Polyethylene Terephthalate Glycol Mold. . 2018 doi: 10.29328/journal.jnnd.1001016; 2: 052-064

Recently Viewed

-

Treatment Outcome in Patients with Myofascial Orofacial Pain: A Randomized Clinical TrialAnders Wänman*, Susanna Marklund, Negin Yekkalam. Treatment Outcome in Patients with Myofascial Orofacial Pain: A Randomized Clinical Trial. J Oral Health Craniofac Sci. 2024: doi: 10.29328/journal.johcs.1001046; 9: 001-008

-

Hygiene and Care Protocols for Implant-supported Dental Prostheses in Patients with DiabetesHakob Khachatryan, Emma Boshnaghyan, Sevak Papoyan, Gagik Hakobyan*. Hygiene and Care Protocols for Implant-supported Dental Prostheses in Patients with Diabetes. J Oral Health Craniofac Sci. 2024: doi: 10.29328/journal.johcs.1001047; 9: 009-014

-

Advancing Oral Health and Craniofacial Science through Microchip ImplantsShekufeh Shafeie*. Advancing Oral Health and Craniofacial Science through Microchip Implants. J Oral Health Craniofac Sci. 2024: doi: 10.29328/journal.johcs.1001048; 9: 015-018

-

Texture Analysis of Hard Tissue Changes after Sinus Lift Surgery with Allograft and XenograftMohammad Azimzadeh, Farzad Esmaeili, Narges Bayat, Kasra Rahimipour, Amir Ebrahimpour Tolouei*. Texture Analysis of Hard Tissue Changes after Sinus Lift Surgery with Allograft and Xenograft. J Oral Health Craniofac Sci. 2024: doi: 10.29328/journal.johcs.1001049; 9: 019-022

-

Awareness and Knowledge of Specialists/Trainers and General Dental Practitioners about Medical-Related Osteonecrosis of the JawsAbdulhamit Taha Koca,Mustafa Bayhan,Yunus Ayberk Demir,Ayse Zeynep Zengin*. Awareness and Knowledge of Specialists/Trainers and General Dental Practitioners about Medical-Related Osteonecrosis of the Jaws. J Oral Health Craniofac Sci. 2024: doi: 10.29328/journal.johcs.1001050; 9: 023-031

Most Viewed

-

Evaluation of Biostimulants Based on Recovered Protein Hydrolysates from Animal By-products as Plant Growth EnhancersH Pérez-Aguilar*, M Lacruz-Asaro, F Arán-Ais. Evaluation of Biostimulants Based on Recovered Protein Hydrolysates from Animal By-products as Plant Growth Enhancers. J Plant Sci Phytopathol. 2023 doi: 10.29328/journal.jpsp.1001104; 7: 042-047

-

Sinonasal Myxoma Extending into the Orbit in a 4-Year Old: A Case PresentationJulian A Purrinos*, Ramzi Younis. Sinonasal Myxoma Extending into the Orbit in a 4-Year Old: A Case Presentation. Arch Case Rep. 2024 doi: 10.29328/journal.acr.1001099; 8: 075-077

-

Feasibility study of magnetic sensing for detecting single-neuron action potentialsDenis Tonini,Kai Wu,Renata Saha,Jian-Ping Wang*. Feasibility study of magnetic sensing for detecting single-neuron action potentials. Ann Biomed Sci Eng. 2022 doi: 10.29328/journal.abse.1001018; 6: 019-029

-

Pediatric Dysgerminoma: Unveiling a Rare Ovarian TumorFaten Limaiem*, Khalil Saffar, Ahmed Halouani. Pediatric Dysgerminoma: Unveiling a Rare Ovarian Tumor. Arch Case Rep. 2024 doi: 10.29328/journal.acr.1001087; 8: 010-013

-

Physical activity can change the physiological and psychological circumstances during COVID-19 pandemic: A narrative reviewKhashayar Maroufi*. Physical activity can change the physiological and psychological circumstances during COVID-19 pandemic: A narrative review. J Sports Med Ther. 2021 doi: 10.29328/journal.jsmt.1001051; 6: 001-007

HSPI: We're glad you're here. Please click "create a new Query" if you are a new visitor to our website and need further information from us.

If you are already a member of our network and need to keep track of any developments regarding a question you have already submitted, click "take me to my Query."